Our Electronic Design Approach :

At Fernhill Technologies, we excel in electronic system and circuit development through a structured process:

- Concept Development: Tailoring designs to specific client requirements.

- Schematic Design: Crafting analog, digital, and mixed-signal circuits.

- Simulation: Verifying circuit behavior for optimal performance.

- PCB Layout: Creating layouts up to 32 layers, focusing on power efficiency, signal integrity, and thermal management.

We ensure each design is reliable, efficient, and custom-tailored to deliver high-performance results, aligned with the unique goals of our clients.

Our Electronic Design Approach (From Idea - Realization)

At Fernhill Technologies, our Electronic Design Approach (EDA) takes your project from initial concept to a fully realized end product, ensuring precision and performance at every step. By integrating advanced design techniques with rigorous testing, we deliver innovative electronic solutions tailored to your specific needs.

- Requirement Analysis: Identify and document the specific needs and goals of the project.

- Architecture & System Specification: Define the overall system architecture and detailed specifications for hardware, software, and mechanical components.

- Hardware Architecture: Design the circuit and PCB layout, followed by simulation and BOM optimization.

- Firmware Architecture: Develop platform software, including drivers, BSP, firmware, and middleware. Customize RTOS and create abstraction layers.

- Mechanical Engineering: Integrate mechanical design with electronic expertise, focusing on reliability analysis and prototype manufacturing.

- Integration and Testing: Conduct board verification, software validation, system integration, and comprehensive testing to ensure all components work seamlessly together.

- Manufacturing and Support: Move to PCB fabrication, assembly, and volume manufacturing. Establish manufacturing test benches and provide ongoing product support and maintenance.

Our Expertise

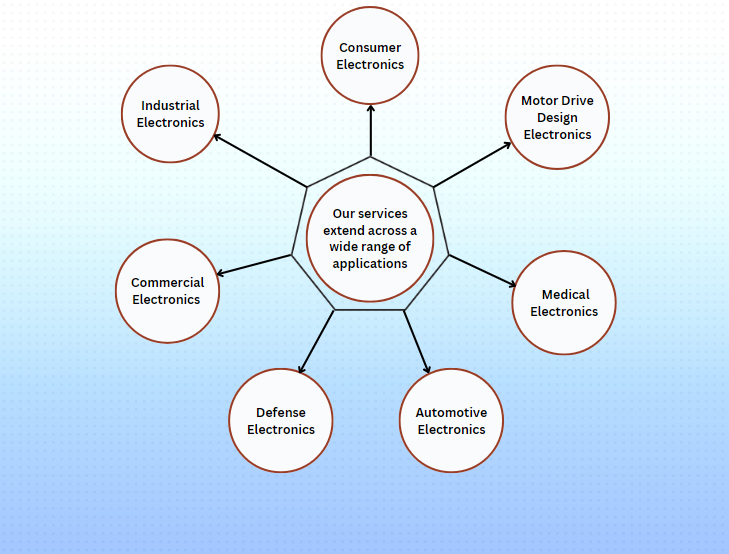

At Fernhill Technologies, our journey in electronic design is not just about creating circuits and systems; it's about crafting solutions that resonate across various domains, from Consumer, Industrial, Defense, Medical, commercial, and Automotive electronics. Our story is one of innovation, dedication, and the relentless pursuit of excellence.

Digital Electronics:

Crafting intricate digital circuits that power everything from smart gadgets to sophisticated industrial machines.

Analog Electronics:

Designing precision analog circuits that ensure accurate signal processing in diverse applications.

Power Electronics:

Developing efficient power management solutions that are critical for everything from consumer devices to industrial systems.

Mixed-Signal Electronics:

Creating hybrid designs that seamlessly integrate analog and digital components for advanced functionality.

Wireless Communication Electronics:

Engineering robust wireless systems that ensure seamless connectivity and communication.

Firmware Development :

We design & develop Bare metal and RTOS programming for Microcontroller & Microprocessors 8bit to 32-bit.

Our Story from

Design

Development

Development

Deliveries

Deliveries

1. The Genesis: Concept Development

Every great product begins with a spark of innovation. At Fernhill Technologies, customers bring us their groundbreaking concepts, which we expertly transform into reality.

- The journey starts with concept development, where our engineers and designers engage in creative brainstorming.

- This leads to a well-drafted initial blueprint, essential for the product’s success.

- We prioritize detailed planning, addressing requirements, challenges, and possibilities to ensure a solid foundation.

- From that initial idea to the final product, we remain dedicated to turning vision into success with precision and creativity.

2. The Blueprint: Schematic Design

Once the concept is finalized, we advance to the schematic design phase. This involves:

- Meticulously planning the role and connection of each component.

- Ensuring optimal alignment of elements for top performance.

- Whether it's digital, analog, power electronics, or wireless communication, every design is crafted with precision.

- Special focus on motor drivers and mixed-signal circuits, ensuring system integrity.

- This stage transforms the idea into functional design, laying the groundwork for the product's physical and operational success.

3. The Testing Ground: Simulation

Simulation is where designs are put to the test:

- We rigorously test and verify designs using tools like Proteus, KiCad, OrCAD, Eagle, EasyEDA, ExpressPCB, and Fritzing.

- This phase helps identify potential issues early, ensuring robust, reliable products.

- For advanced needs, we collaborate with third-party experts on Altium, Matlab, and PSPICE.

- We specialize in simulating single, double, and multilayer boards, tackling complex designs.

- Our approach adapts to customer needs and licensing requirements, ensuring thorough testing for long-lasting performance.

4. Crafting the Heart

4.1 PCB Layout Simulation

Simulation is our proving ground. Using advanced tools and open-source software, we meticulously test and refine our PCB designs before fabrication, ensuring we optimize heat dissipation. This stage allows us to identify and rectify any potential issues, ensuring that our designs are robust and efficient.

4.2 PCB Fabrication

Frontier Technologies outsources PCBs through reputable suppliers. Rigid standards ensure quality and fidelity to produce single-sided, double-sided, or multi-layer boards. We maintain close relationships with fabricators to optimize the QA/QC process and pricing builds. For high-end designs, we provide recommended third-party manufacturers to ensure quality.

4.3 Component Procurement and Assembly

We source components from trusted suppliers like Mouser, Digikey, and Element14. For some quantities, we use third-party suppliers to handle component procurement and assembly. Through this, we ensure reliable and efficient sourcing of components. We adhere to strict quality control measures during the assembly process. This approach ensures high-quality finished components and precise assembly, allowing us to maintain superior design. We deliver thoroughly tested, assembly-line quality consistent products.

4.4 PCB Testing and Quality Control

At Frontier Technologies, we design PCBs up to 16 layers, collaborating with circuit experts at specialized test labs using Flying Probe & Bed-of-Nails. We utilize X-ray inspection for BGA and dense multi-layer boards when necessary. Our comprehensive testing includes thermal spray, weather, signal integrity, emissions, and vibration tests. This rigorous approach ensures each PCB meets our exacting standards. Every PCB undergoes meticulous inspection, delivering reliable, meticulously crafted PCBs suitable for any environment.

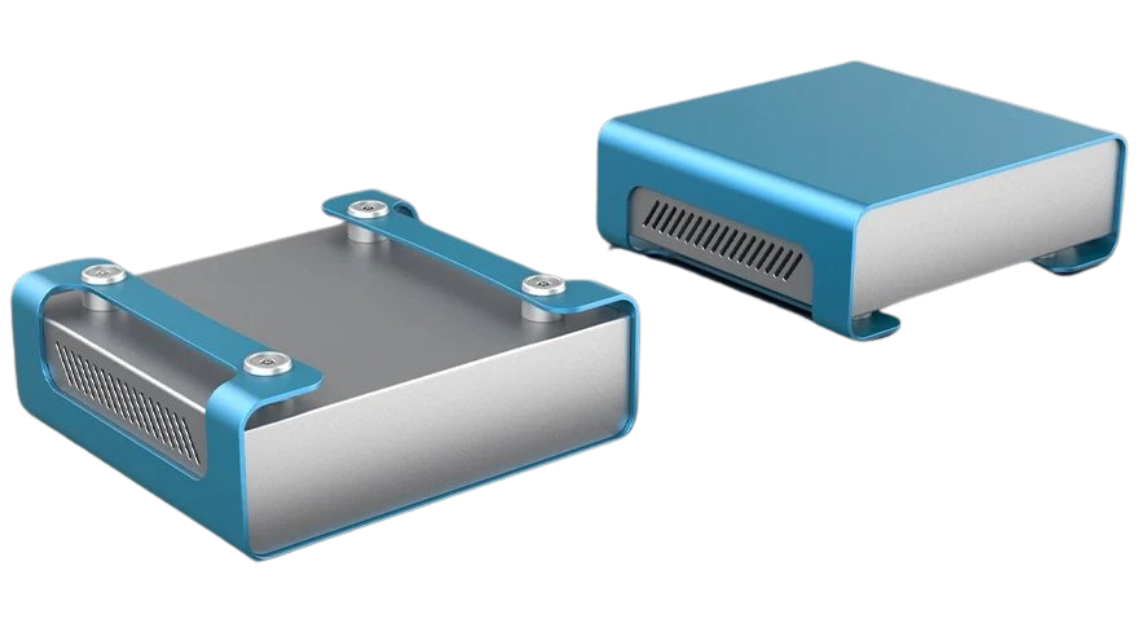

5. The Final Touch: Enclosure Design

At Fernhill, we prioritize both functionality and aesthetics in our product design. Here’s how we ensure our enclosures excel in both areas:

- Protection and User Experience: Our enclosures are designed to safeguard electronic components while enhancing the user experience.

- Tailored Solutions: Whether for sleek consumer devices or rugged industrial systems, we customize our enclosures to meet environmental demands.

- IP Ratings for Durability:

- IP65: Dust-tight and water-resistant

- IP66: Strong water jets

- IP67: Immersion protection up to 1 meter

- IP68: Deeper immersion protection

- IP69: High-pressure, high-temperature cleaning

- Advanced Design Tools: We use SolidWorks, AutoCAD, and Mentor Graphics to design enclosures that excel in both form and function.

- Collaboration for Quality: We work with trusted third-party vendors to access specialized tools and ensure high-quality, reliable enclosures suited to every project’s needs.

Diverse Applications: Tailored Solutions

Partnering for Excellence: Third-Party Collaborations

We understand that achieving excellence requires collaboration. Over the years, we have forged strong partnerships with third-party vendors who provide specialized services in advanced PCB design, simulations, analyzers, manufacturing, testing, and component supply. These collaborations allow us to leverage their expertise, ensuring on-time delivery, competitive cost, and the highest quality.

Our Commitment: Delivering Excellence

From concept to final product, every step of our process is infused with a commitment to excellence. At Fernhill Technologies, we don’t just create electronic designs; we create solutions that drive progress and innovation. Our story is one of passion, precision, and the relentless pursuit of creating products that make a difference in the world. Join us on this journey, and let’s create the future of electronics together.